| SPECIFICATIONS | FHC-120EA |

|---|---|

| Spindle Motor (kw(hp)) | 5 HP(3.75kw) x 2 ps(Standard) 2 HP(1.5kw) ~ 5HP(3.75kw) (Optional) |

| Spindle Speed (rpm) | 300 ~ 1500rpm (Standard) 800 ~ 2500rpm (Optional) |

| Frequency Converter (kw) | 5HP~15HP (3.75kw~11kw) |

| Sever-Motor Feeding (kw(hp)) | 1.5kw (Optional) |

| Air Pressure (mpa) | 6~8 kg/cm², 120ml/min , 0.6~0.8mpa |

| Applicable Materals | Various pipes including steel, iron, stainless steel, aluminum, bronze |

| Pipe and Bar O.D. Outter I.D. Inner Angle and End Face(mm) |

A type workpiece Ø12~Ø60, B type workpiece Ø50~Ø90, C type workpiece Ø80~Ø120, thickness T0.8~5mm According to length of A、B or C type workpiece |

| Workpiece Length | A type workpiece L25~300mm B type workpiece L25~250mm C type workpiece L25~200mm According to outside of A、B or C type workpiece |

| Cutterhead (mm) | O.D Ø130 Ø12~Ø52,(MAX Ø60) (Standard) O.D Ø170 Ø50~Ø120, (Optional) |

| Machine Dimensions (LxWxH) (mm) | 2330x1630x2130 |

| Packing Dimensions (LxWxH) (mm) | 2400x1700x2200 |

| N.W. (kg) | 2200 kg |

| G.W. (kg) | 2500 kg |

| Model | THC-B90NC |

|---|---|

| Cutting Capacity | |

| Round Solid Bar (mm) | 15~90 |

| Square Solid Bar (mm) | 15~80 |

| Rectangle (mm) | 15~80 |

| Round Pipe (mm) | 15~90 |

| Square Pipe (mm) | 15~80 |

| Maximum Length of Head Cut (mm) | 10 ~ 60 |

| Tail Length Shorten Facility (mm) | 20~25 (oprional) |

| Waste Material Length at Tail End (mm) | 55~(55 +π Cutting length) |

| Feeding Length (mm) | 5~600 Continuous cycles |

| Manually Stack Line-up Loader Capacity (kg) | 3000 |

| Material Length (mm) | 2000 ~ 6000 |

| Material Loading Width (mm) | 950 |

| Machine Specifications | THC-B90NC |

|---|---|

| TCT Carbide Sawblade | Ø285 × 2.0~Ø330 × 2.25 |

| Pin Holes + Bore (mm) | 4 × Ø11 × PCD63 × Ø32 |

| TIP Aluminum Carbide Sawblade (mm) | -- |

| Pin Holes + Bore (mm) | -- |

| HSS Sawblade (mm) | Ø285~Ø330/t2.0~2.5 |

| Spindle Motor (kw) | 9 (12HP) |

| Spindle Speeds (rpm) | 50~200 |

| Frequency Inverter (kw) | 11 (12HP) |

| Hydraulic Pump Motor (kw) | 2.2 (3HP) |

| Operation Pressure (mpa) | 7mpa 70kg/cm² |

| Oil Tank Capacity (ℓ) | About 120 |

| Air Pressure (mpa) | 0.4~0.6mpa 4~6kg/cm² |

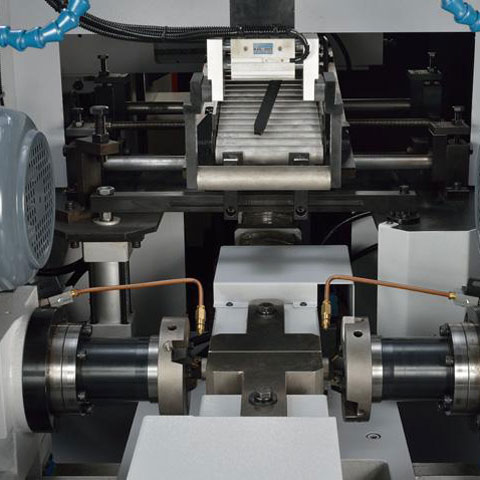

| Feed Drive | AC servo-motor (1.3kw or 1.5kw) drive ball screw for feeding |

| Sawhead Drive | AC servo-motor (1.8kw or 2.0kw) + drive ball screw for cutting (optional) |

| Tail End Gripping Drive | AC servo-motor (0.85kw or 1kw) + drive ball screw for gripping |

| Main Vise + Infeed Vise | Horizontal/Vertical hydraulic type, Infeed hydraulic vise |

| Machine Dimensions and Weight | THC-B90NC |

|---|---|

| Machine Size (mm) | 6860 x 1889 x 1530 |

| Weight (Machine + Feeder) (kg) | 2800 |

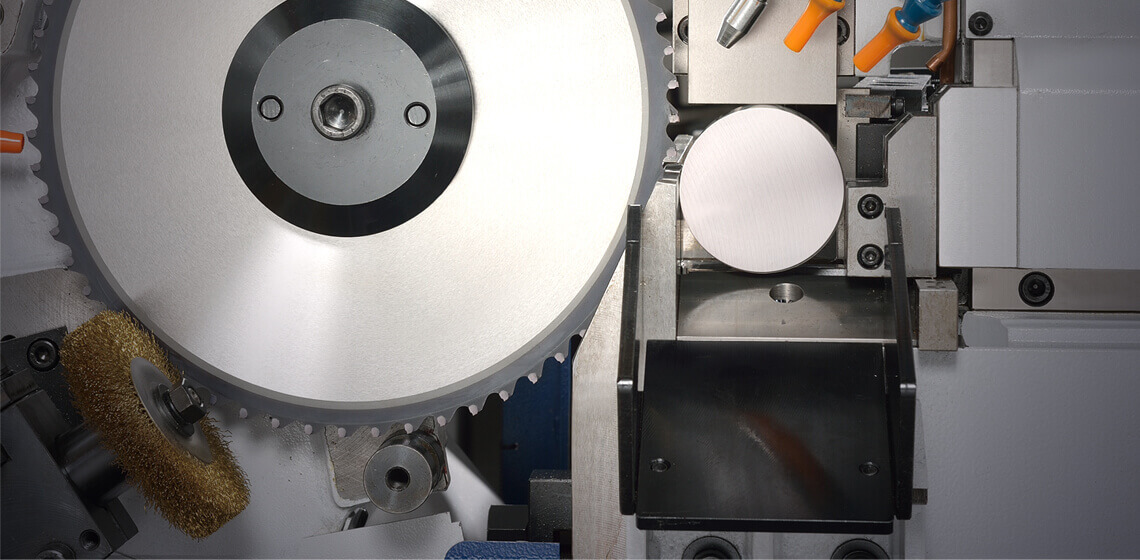

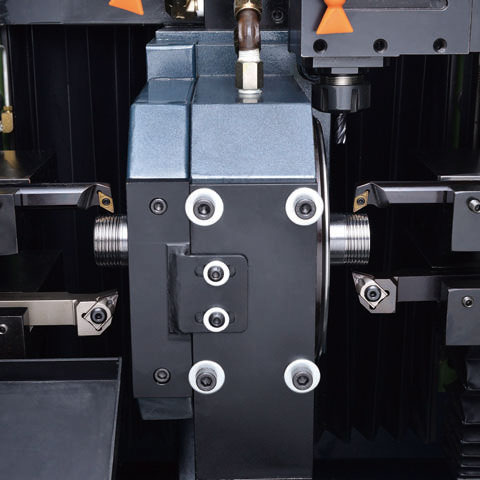

FHC-120EA

1.Standard cutterhead for left and right x 2 sets

2. Circular clamp two pieces in one set.

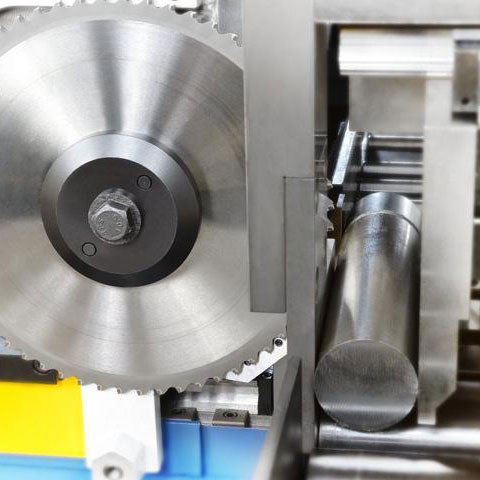

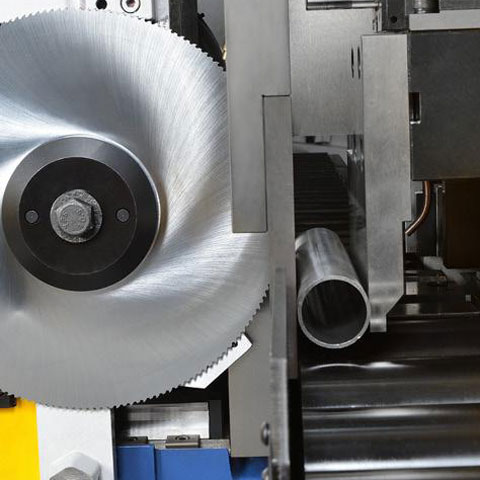

THC-B90NC

1.Sawblade Gap Compensation Device

2.Tungsteen Pad for Sawblade Run-out

3.Wheel Brush

4.Scraper Type Chip Conveyor

5.Mist Cooling Device

6.Cutting Fluid Cooling Device

7.Angular Steel Slicing Device

8.Work Light

FHC-120EA

1.Custom cutterhead

2.Custom circular clamp

3.Vibration or ATF. Automatic carriage feeder

4.End Knurling Device

5.Mist cooling device

THC-B90NC

1.TCT Carbide Sawblade

2.HSS Sawblade

3.Oil Mist Collector

4.Cutting Fluid

5.Automatic Roller Out Feeding Device

6.Manual Storage Loader

7.Automatic Feeding Equipment

8.Automatic Magazine Loader

9.Automatic Locating Equipment